Insulating Glass Unit

Insulating Glass Unit / Twin Glass

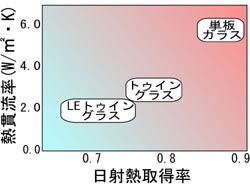

Twin Glass is a highly insulating product that traps air between two panes of glass. Its thermal transmittance is 2.9 W/m²·K, providing roughly twice the insulation performance of single glass (5.9 W/m²·K). Among our insulating glass lineup, it offers excellent solar heat gain, drawing in weak winter sunlight while maintaining a comfortable indoor environment through its high thermal insulation.

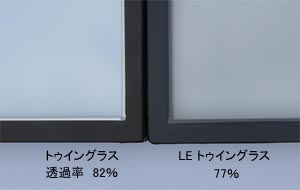

Twin Glass constructed with standard glass offers slightly lower insulation performance than higher-end products, but it has the best transparency in our insulating glass lineup. It is ideal for windows where you want to enjoy the view outside or for show windows where interior displays need to stand out.

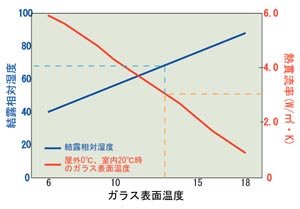

Condensation occurs when the indoor-side glass surface temperature is lower than room temperature and the air near the glass is cooled, causing relative humidity near the surface to exceed 100%. Thanks to its high thermal insulation, Twin Glass keeps the indoor glass surface temperature close to room temperature even in conditions where condensation is likely, thereby suppressing condensation.

Under conditions of 0 °C outdoors and 20 °C indoors, the indoor-side glass surface temperature of Twin Glass is approximately 13 °C, and condensation is hardly generated up to around 65% relative humidity.

(Values are based on our internal simulation. The influence of spacers and frames is excluded.)

Minimum dimensions: 180×350mm

Maximum dimensions: 2,500×3,500mm

Maximum weight: 350kg

Total thickness: 18–52mm

- Cutting or processing after manufacture is not possible. Please specify dimensions and shapes accurately when ordering.

- For products with non-rectangular shapes such as circular types, please contact us in advance.

- Due to the structure, expansion and contraction caused by temperature and pressure changes may occasionally create interference fringes at the center of the glass.

- When using frosted (etched) or patterned glass, the embossed surface is, in principle, oriented toward the cavity side.

- In high-temperature environments (especially above 70 °C), sealants and other materials may deteriorate, significantly reducing the service life of the insulating glass.

- Use appropriate sealants, backer rods, setting blocks, and other accessories so that interlayers and sealants are not adversely affected.

- When used at high altitudes (particularly above 600 m above sea level) or transported by air, expansion breakage may occur. Please contact us in advance.