Laminated Glass

Laminated Glass / Seifer

While the interlayer film alone is a flexible sheet that can easily be cut with a knife, when sandwiched between two sheets of glass it becomes a tough laminated glass that combines the flexibility and tear resistance of the film with the hardness of glass. Even if the glass breaks, the fragments remain adhered to the interlayer, providing high safety and making it difficult for an opening to form.

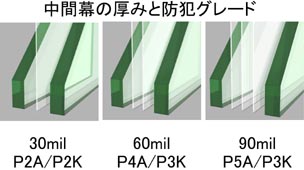

Laminated glass using an interlayer of 30 mil (approx. 0.8 mm) or more is listed in the “Crime Prevention Building Parts Catalog” by the joint public‑ private conference for the development and dissemination of high‑security building components as a glass with excellent security performance.

Laminated glass using an interlayer of 30 mil (approx. 0.8 mm) or more is listed in the “Crime Prevention Building Parts Catalog” by the joint public‑ private conference for the development and dissemination of high‑security building components as a glass with excellent security performance.

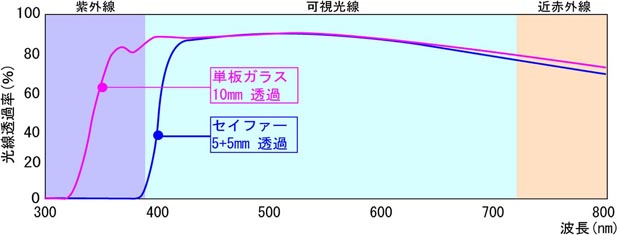

The interlayer of laminated glass is highly transparent and its refractive index is close to that of glass, so the appearance (visible light transmittance and reflectance) is almost the same as that of monolithic glass of the same thickness, while blocking only the undesirable ultraviolet rays.

Minimum dimensions: 210×295mm

Maximum dimensions: 2,400×4,500mm

Maximum weight: 1,000kg

Glass thickness: 3+3–60mm

- The interlayer may foam in environments exceeding 70 °C. Avoid use in such high‑temperature conditions.

- Cutting or processing after manufacture is not possible. Please specify dimensions and shapes accurately when ordering.

- Exposed edges may absorb moisture into the interlayer and cause delamination.

- When using exposed edges or butt‑jointed configurations, a dedicated type of laminated glass is required. Please consult us.

- Use appropriate sealants, backer rods, setting blocks, and other accessories so that the interlayer is not adversely affected.